RS-GEOTEXTILE

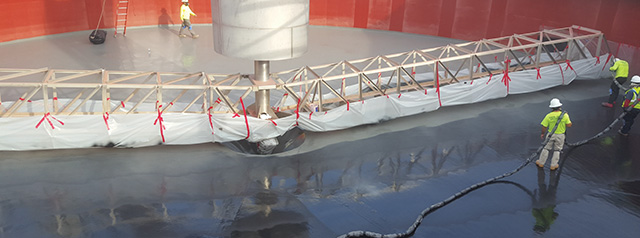

RS GeoTextile Polyurea Sprayed Containment Liner is a pre-sprayed composite panel system comprised of non-woven polypropylene geotextile and a 100% solids pure polyurea membrane system. RS GeoTextile may be used by itself or in combination with other materials to produce wearing courses and resilient surfaces on a variety of substrates. RS GeoTextile membrane panel systems are inert; panel components will not hydrolyze, leach, or contaminate other materials, and surfaces are bondable and paintable. RS GeoTextile panel systems are relatively moisture and temperature insensitive, allowing installation in the most problematic ambient conditions. Standard RS GeoTextile panels utilize a 6 oz. geotextile to insure durability and protect against handling damage. The standard 15’ (15.24m) X 40’ (12.2m), 600ft2 (55.74m2) panels weigh approximately 200 pounds (90.71kg) and can be conveniently moved and handled by the field crew. The approximate 4” (10.16cm) – 6” (15.24cm) seaming edge strips provide sufficient overlap to allow quality installation even in the most difficult geometries. Panels up to 15’ (15.24m) X 75’ (22.86m) , 1,125ft2 (104.51m2) are available.

Properties

Fabric Burst Strength (ASTM D751): 4,300 – 4,600 psi (302.31-323.41kg/cm²)

Puncture Resistance (ASTM D751): 95-110 lbs (43.09-49.89kg)Open to Use: 1 hour

Tensile Strength (ASTM D638): 1000-1200 psi (70.3-84.3kg/cm²)Elongation at Break (ASTM D638): 320-400%

Tear Strength (ASTM D624): 355-385 lbf/in (63.39-68.75 kgf/cm)Hardness Shore D (ASTM D2240): 35

Tabor Abrasion, 1000 revs, H-18 (ASTM D4060): 180 mg wt loss

Typical Uses

Water ponding

Secondary Contain-ment

Unrepairable concrete

Below/Above grade water proofing

Water and Wastewater treatment

Lift station manholes

Wet wells

Penetration and termi-nations

Advantages

100% Solids, no VOCs

Ease of installation

Tough, Seamless Elas-tomeric membrane

Pre-manufactured in automated controlled environment

Excellent thermal sta-bility Minimal downtime

Flexible in colder tem-peratures

Good UV Stability

Low permeance rate

No need for heat weld-ed seams